Regelbunden rengöring av kyltorn förbättrar effektiviteten, minskar energikostnader och förhindrar hälsorisker som legionella. Våra experter säkerställer en trygg och effektiv sanering.

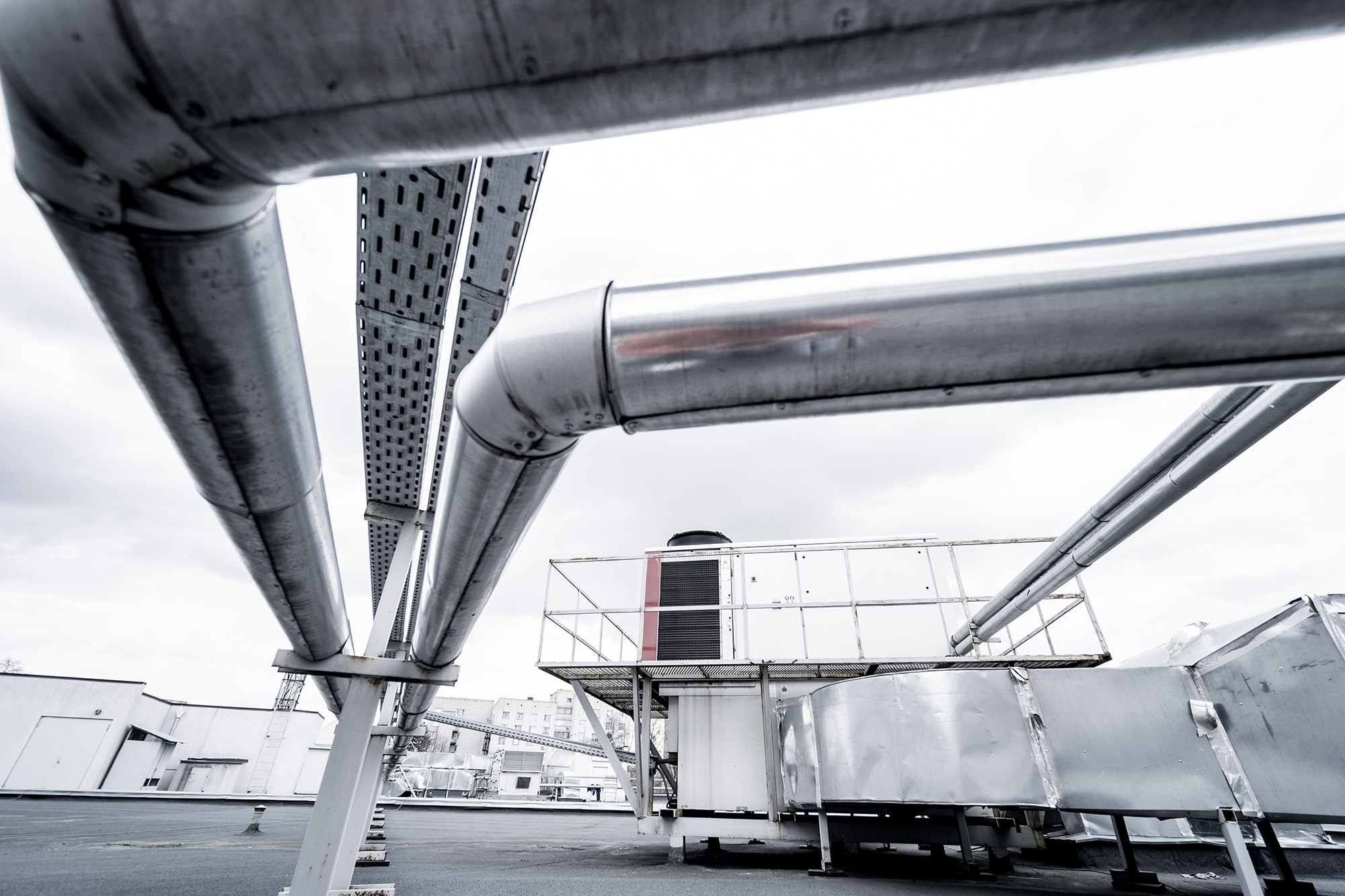

Kyltorn är centrala för att hålla stora byggnader och industrilokaler svala och behagliga. Genom att kyla ner luften spelar kyltorn en avgörande roll i att skapa en optimal inomhusmiljö för allt från kontorsbyggnader och shoppinggallerior till industriproduktioner. För att säkerställa effektiv drift och minimera hälsorisker krävs regelbunden och professionell rengöring av kyltorn.

Kyltorn utsätts för många föroreningar, såsom damm, pollen och smuts, vilket kan leda till försämrad effektivitet och till och med skada systemet om det inte rengörs regelbundet. Dessutom kan fukt leda till tillväxt av mögel och bakterier, vilket kan bli en hälsorisk för de som vistas i byggnaden. Genom regelbunden rengöring håller du kyltornet effektivt och minimerar hälsoriskerna.

Fördelar med

Effektiv rengöring som minimerar driftstopp och sparar tid.

Höjer prestandan och minskar energiförbrukningen.

Kostnadseffektivt med snabb återbetalning på 6-12 månader.

Miljövänlig metod kemikalier och avfall.

Vår process är utformad för att ge dig en trygg och effektiv tjänst från start till mål. Vi arbetar metodiskt för att identifiera problem, genomföra noggranna åtgärder och ge vägledning som säkerställer långsiktiga resultat.

Vi utför en grundlig inspektion för att fastställa smutsens omfattning och vilken metod som passar bäst.

NEO-metoden implementeras, vilket säkerställer att alla avlagringar tas bort utan att skada stallaget.

Efter rengöringen görs en slutlig inspektion för att säkerställa maximal prestanda och hållbarhet.

Kyltorn är känsliga för vissa rengöringsmetoder, och konventionell högtryckstvätt är inte alltid lämplig. Högtryckstvätt kan orsaka mikroskador och sprickor på kyltornets ytor, vilket kan försämra både effektivitet och livslängd. Istället använder vi specialanpassade rengöringsmetoder som effektivt tar bort smuts, alger och mögel utan att skada tornet. Vårt team är erfarna och använder säkra metoder för att säkerställa att ditt kyltorn förblir i bästa skick.

Håller kyltornet i optimalt skick för effektiv kylning.

Förhindrar tillväxt av legionella, mögel och andra skadliga ämnen.

Skyddar ytor och komponenter från skador, vilket förlänger systemets livslängd.

Vill du optimera energikostnaderna och förbättra inomhusklimatet i din fastighet?

Klicka på knappen för en kostnadsfri prisförfrågan. Låt oss hjälpa dig att skapa en energieffektiv och hållbar drift genom professionell rengöring!

Här besvarar vi några utav det vanligaste frågorna vi får kring kyltorn.

Det rekommenderas att kyltorn rengörs minst en gång per år, men i vissa miljöer eller under högt belastade perioder kan det behövas oftare. Regelbundna inspektioner kan hjälpa till att fastställa ett optimalt rengöringsschema.

Ett smutsigt kyltorn kan samla på sig bakterier och mögel, inklusive legionella, som kan spridas via luftburna vattendroppar och orsaka allvarliga sjukdomar som legionärssjuka.

Ett rent kyltorn fungerar mer effektivt, vilket minskar energiförbrukningen och sänker driftskostnaderna. Regelbunden rengöring är därför en investering som bidrar till lägre energikostnader på lång sikt.

Har du ytterligare frågor eller bara vill ta ett samtal. Tveka inte på att kontakta oss!

Vi erbjuder professionella lösningar för allt från mögelsanering till rengöring av kyltorn, skräddarsydda för att säkerställa en säker och ren miljö i din fastighet.

Vår vision är att vara den mest erfarna och kompetenta energioptimeraren på marknaden. Med NEO-metoden är vi marknadsledande med denna specialrengöring för värme- och kylanläggningar för fastighet och industri.